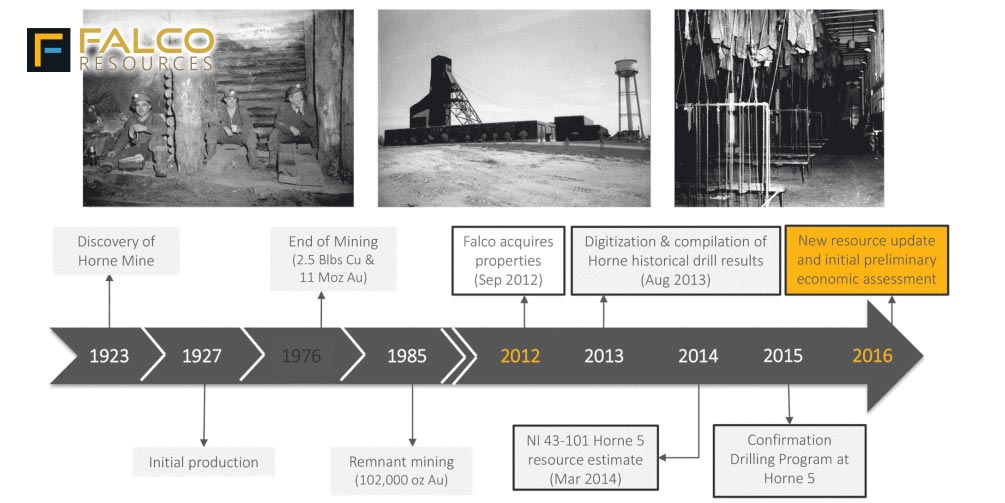

Falco Resources utilize a highly technical digitization and data mining tactics to move over 80 years of historical data into the 21st century. The bundling of this proprietary data with modern day technology, allowed company to ‘rediscover’ the Horne 5 deposit.

Below is our interview with Luc Lessard, President & CEO of Falco Resources.

Q: Tell us something more about Falco Resources and your history?

A: Falco Resources was founded in 2012. Since then, the company spent a tremendous amount of time digitizing historical analog data that had been kept in a vault for nearly 40 years. This allowed us to release a maiden resource in 2014, and following an extensive confirmation drilling program in 2015, to release our current resource of 6.6 mm ounces of gold-equivalent ounces.

Q: What advantage does Falco have over its competitors?

A: We own a very large land position in one of Canada’s most successful mining camp.

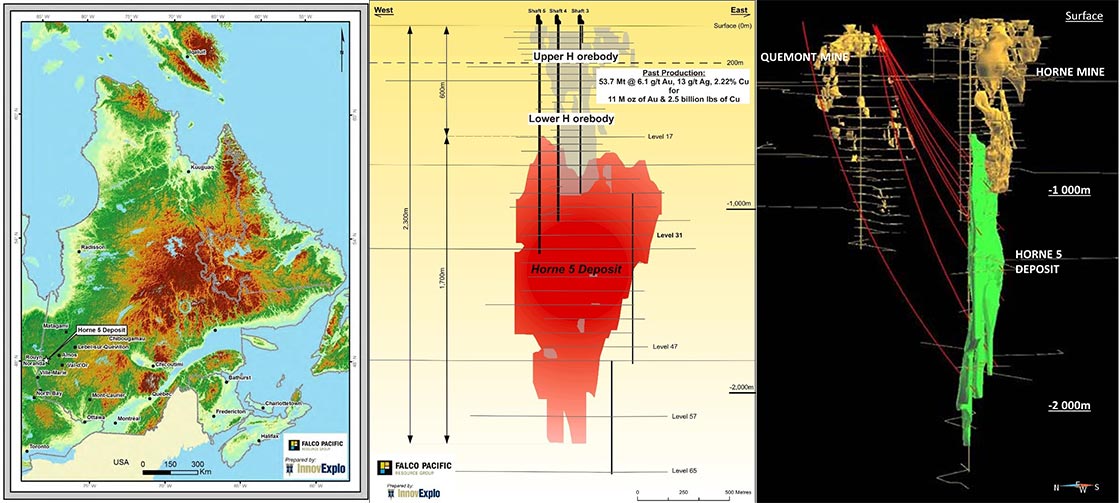

We have the benefit of having access to close to 100 years of historical data. The historical Horne mine commenced production in 1927 and produced until 1976. The database is still intact and obviously contains several opportunities that have yet to be found. Our management team has a tremendous amount of experience in building mines. Quebec has always been our premier jurisdiction. We know the people, we have worked with the people and the communities know that we operate in a very diligent and professional manner. Additionally, we are operating in an environment where infrastructure is already present. We have access to hydro power, rail and highway, we are next to a great mining town and have access to a superb labour pool, and additionally major suppliers are within 15 km of the mine site. Today, Rouyn-Noranda is one of the best place in the world to build a mine.

Q: You’ve recently announced that the company has filed on SEDAR a National Instrument 43-101 compliant technical report for Horne 5 gold project tell us something more?

A: Yes, we have released an updated resource of 6.6 mm ounces of gold-equivalent, which 81% is in the Indicated category. In 2015, we conducted 17,300 m of confirmation drilling to confirm the historical database and geological model. The program was very successful and allowed to increase the maiden resource significantly. The successful confirmation program allowed us to use the 305,000m of historical drilling that was done by Noranda during the production era. The majority of the Noranda drilling was conducted as radiating “fan drilling” on 15m spacing from 40 underground working levels developed throughout the deposit, which obviously gave us much comfort in the data.

Q: What are your plans for next four months?

A: We are currently working at releasing the initial Preliminary Economic Assessment on the deposit. We are planning on releasing the report in the second quarter of 2016. Following its release, we will be initiating the Feasibility Study and the Environmental Impact Assessment which we foresee to complete in the first half of 2017. Additionally, we have done limited exploration drilling on the rest of the property. For 2016, we have targeted two targets in the vicinity of the Horne 5 deposit which we believe offers a big growth potential.

Q: What’s the best thing about Falco Resources that people might not know about?

A: Our project is on the fast-track to development and construction. We will benefit greatly from having available underground infrastructure. After a thorough analysis in 2015, we demonstrated that the Quemont #2 shaft would be available for production purposes. The Quémont #2 shaft will need to be rehabilitated to current production standards, however it will not have to be widened to accommodate larger skips. This will help reduce capital requirements to build the mine, but most importantly reduce the timeline to production. Additionally, the historical workings located in the upper portion of the ore body offer several openings where waste material and tailings could be sent and disposed of. These openings will enable us to minimize the impact on surface and manage tailings efficiently.

Activate Social Media: