Below is our recent interview with Thor Kallestad, CEO of DataCloud:

Q: Could you provide our readers with a brief introduction to DataCloud?

A: DataCloud transforms it’s clients drill and blast operations with advanced rock measurements and analytics. Our team is a combination of Silicon Valley techies and geoscience experts. We’ve built a solution for the mining industry that gives producing mines a granular look at their resource while drilling blast holes. It’s a concept that is widely used in Oil and Gas, where many of our founders began their careers in the natural resources. We are based on the American West Coast and have been growing internationally since 2016. We opened a Perth, Western Australia office in 2018 and a Vancouver, Canada office this year for our growing demand in the regions.

Q: You’ve recently raised $4M in funding; could you tell us something more?

A: The challenges of paving our own pathway in this industry only intensified after we raised funds. We have a built product that brings real value to mining companies, and the floodgates are open with seemingly endless possibilities. This makes it easy to maintain motivation and creative momentum while staying focused on our client’s specific production goals. We simultaneously must keep delivering positive results and coming up with creative solutions to keep our clients ahead of the game.

Recommended: The Self Leadership LAB Helps Drive Results From The Inside Out

Recommended: The Self Leadership LAB Helps Drive Results From The Inside Out

Q: Can you give us insights into your solutions?

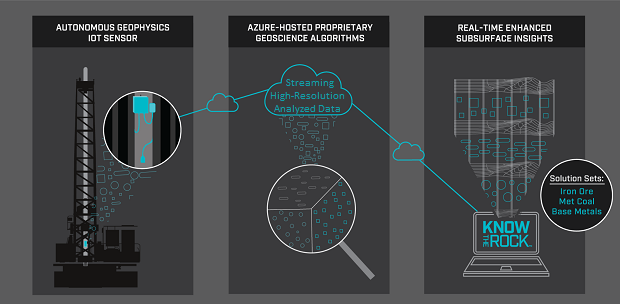

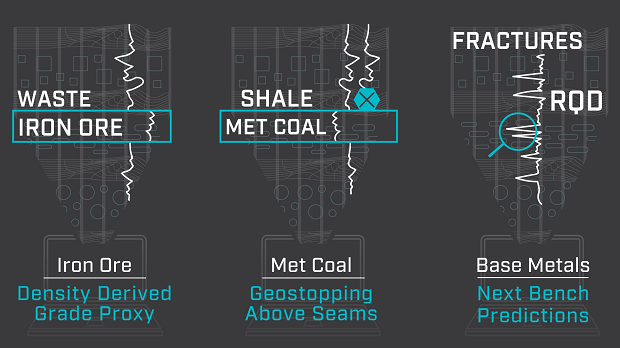

A: Our IoT sensors, computing decives, and cloud-based software work together to give mining companies an intelligent orebody evaluation platform to truly know the rock. This increases efficiency, safety, and profits during production. Clients install our IoT sensors on their drills to record rock mass data while drilling blast holes. Our proprietary algorithms transform that data into polished insights, which are available in real-time on any browser or smart device. Providing a granular look at their resource improves grade control, enables a continuously updating high-resolution block model, and delivers highly accurate boundary detection between ore and waste. DataCloud’s offering is very user friendly as we take care of everything for the client behind the scenes. We can export real-time rock mass characterization data directly into a client’s block model so that it can be picked up by their workflows downstream with minimal disruption.

Q: A key driver of DataCloud’s technology solutions is based on the concept of fragmentation optimization – could you explain that a bit more?

A: Ore is what mining companies sell to industries who create materials that build our world. The more ore you can extract from the mine, and the less waste rock you process, the more efficient the whole process becomes. A mine site needs to break valuable rocks down to the size that their mill was designed to crush. They need to spend as little cost and time as possible breaking up rock without reducing their equipment life.

The only way to do either of these with extreme precision and the utmost safety is by using rock mass intelligence. A mine site must know exactly where the faults, joints, and waste/ore boundaries are located, in addition to the mechanical properties of the orebody. The milluses this knowledge during the blasting process to reduce the orebody to fragments of rock with a uniform and consistent size distribution that its mill was designed to optimally process. In addition, there is great value in grade control; knowing the ratio and location of ore and waste inside those fragmented pieces. Our technology makes it clear what this ratio is for any given section of rock which is crucial to how they will separate and treat the rocks to create their final product to sell. By optimizing fragmentation and ore control, mining companies can see significant increases in throughput and revenue at their operations.

Recommended: Invest Latam Connects Investors With Latin American Companies To Negotiate Loans

Recommended: Invest Latam Connects Investors With Latin American Companies To Negotiate Loans

Q: I read something about your partnership with Microsoft – how did that start?

A: We utilize Azure for our cloud-computing component to our solutions. They are just as keen as we are to be apart of clean tech initiatives inside a globally impactful industry. It is a mutually beneficial relationship; they have an entrance to a different avenue of mining (other than the industry’s massive Excel use), and we have access to safe, fast, top of the line cloud architecture and support for our solutions. Our Microsoft partners in Australia have been excellent go to market partners, showing our solutions to potential clients in the Pilbara and Queensland region.

Q: What are your plans for the future?

A: We are currently expanding our reach in geologies and geographies; going from iron ore, met coal, and copper to lithium, gold, and uranium, and going from Australia and Canada to Chile, South Africa, and Zambia. Our solutions are built for producing open pit mines. We recognize the importance of underground, and exploration, and plan to tailor our technology for those applications in the future.

Activate Social Media: