* – This article has been archived and is no longer updated by our editorial team –

Nikola Labs is a wireless power company with an advantaged far-field technology that converts radio frequency (RF) energy into usable direct current (DC) power. We are a devoted and capable team that includes world-renowned electrical engineers and distinguished business leaders united by a common goal – advancing wireless power into the marketplace.

Below is our recent interview with Will Zell, CEO at Nikola Labs:

Q: Could you provide our readers with a brief introduction to Nikola Labs?

A: Nikola Labs is ushering in electricity’s next great act – the practical transmission of power without wires. In 2014, Nikola Labs spun-out from The Ohio State University’s (OSU) world-renowned ElectroScience Laboratory to commercialize wireless power technology invented by Dr. Chi-Chih Chen, who now serves as our company’s CTO. Our state-of-the-art system converts radio frequency (RF) energy into usable direct current (DC) power, and OSU’s foundational patents are licensed exclusively to Nikola Labs.

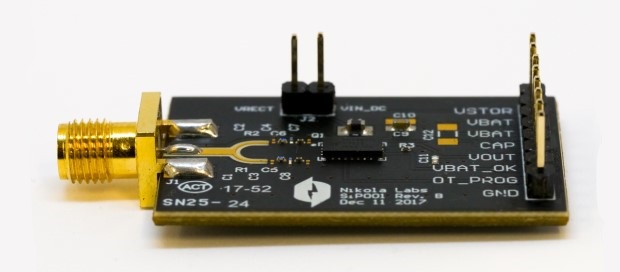

Over the past three and a half years, we have made significant progress to improve the technology and make it suitable for commercial deployment. Working with technology partners Texas Instruments and Skyworks Solutions, the circuitry to convert RF to DC was miniaturized down to a single chip, called INDRA, for the Hindu god of lightning. Additionally, the Nikola team recently launched our first product, PfM, a wireless, 100% maintenance-free, battery-free industrial sensor network that communicates and is powered remotely.

Recommended: Croptracker: Cloud-Based Crop Management Software System Helps Growers Thrive With The Power of Data

Recommended: Croptracker: Cloud-Based Crop Management Software System Helps Growers Thrive With The Power of Data

Q: You’ve recently launched predictive maintenance sensors; could you tell us something more?

A: Our PfM predictive maintenance sensor system is the world’s only completely maintenance-free industrial sensor network that both communicates and sends power wirelessly. We launched PfM at Reliable Plant in Indianapolis where the system received a lot of positive attention from the facility maintenance professionals attending the show.

Unplanned downtime is a significant source of economic loss and frustration for operations and maintenance teams at manufacturing facilities. Predictive maintenance sensors provide powerful insights for understanding the condition of operating assets, which allows machine maintenance experts to be more proactive in avoiding costly unplanned downtime. For this application, and others, wireless power is a game-changer providing the benefits of wireless sensors without the burden of replacing batteries on hundreds or thousands of wireless devices in each plant.

Nikola Labs is now working with an initial set of customers and expects that first deployments of PfM will occur this coming summer.

Check out this video for an overview:

Recommended: Thexyz – Delivers Powerful Email Application For Both Business And Personal Users

Q: What’s the heart of your solutions?

A: At the heart of Nikola Labs’ solutions is the INDRA chip, which was developed with technology partners, Texas Instruments and Skyworks Solutions. The tiny INDRA chip, which measures 5.6mm x 3mm x 0.8mm – less than 1/16 the size of a penny – is a miniaturized version of Nikola Labs’ highly efficient radio frequency to direct current (RF to DC) energy harvesting circuitry. It was specifically designed to power Internet of things (IoT) devices, such as industrial sensors, that with the addition of wireless power can provide uninterrupted data without the need to ever change batteries.

Nikola Labs recently qualified manufacturing sample INDRA chips, provided by Skyworks. Qualification included thorough testing at our engineering lab in Westerville, Ohio (just outside Columbus) to verify sensitivity to RF signals and performance. In these tests, INDRA performed very well, showing best in class sensitivity, producing power at -15 dBm, and high efficiency. Current chips on the market require twice the input power (-12 dBm). The sample chips provided by Skyworks passed all qualifying tests and have now been approved for scale manufacturing, which will begin in May or June of this year.

Q: How does your smart city concept look like?

A: We are excited about the opportunity to apply our technology to smart city concepts. We plan to share information about smart city, and other applications, of Nikola technology when these products are closer to launch.

Q: Can you provide some real word use-cases that we can expect to see?

A: One exciting real world use-case we’ll see very soon is in manufacturing. Manufacturing plants rely on machines to move, mix, make, process, package, pallet, and so much more. These machines are driven by motors with gearboxes and axles on bearings. Every motor and machine requires maintenance, but ‘how much?’ and ‘how soon?’ Historically, these questions have been difficult to answer and often completely unanswerable. So, the choice was either run equipment until failure or perform scheduled maintenance to avoid unexpected shutdowns. The latter became known as Preventive Maintenance, or simply PM. PM was best practice in industry for decades, but new tech is offering a better way, Predictive Maintenance, or PdM. PdM reduces costs and allows deployment of constrained resources to more productive uses. The availability of low cost wireless sensors enables the monitoring of vibration, temperature and other parameters that together with sophisticated software can foretell equipment failures, and better guide maintenance efforts.

PdM offers two key benefits: improved process uptime and lower maintenance cost, both of which directly impact profitability. With such promise, PdM should be in every factory, but it’s not. A key factor behind the slow adoption, ironically, is the burden associated with placing hundreds or thousands of wired or battery-powered sensors in any given facility. Even with years long anticipated battery life, they eventually need to be replaced or recharged, and the prospect of adding a new maintenance activity when the goal is to reduce maintenance is a significant deterrent.

Wireless power is the answer. By reliably providing consistent power at a distance, Nikola Labs’ technology enables PdM sensors to offer all the benefits without the added burden of changing batteries. A single transponder transmits power to multiple sensors and acts as a communication hub gathering the vibration, temperature and other data periodically and sending this information to the cloud or a local network, where it is visualized and analyzed to make maintenance decisions. Decisions that ultimately increase uptime and help prevent costly downtime.

Recommended: Xait Helps You Create Documents Faster & Better, Redefining Document Collaboration

Recommended: Xait Helps You Create Documents Faster & Better, Redefining Document Collaboration

Q: What does the future hold? Where is the company headed?

A: Nikola Labs is creating the future with our advantaged wireless power technology. Due to the broad applicability of our technology, opportunities abound in the following market verticals:

• Smart Cities – Nikola Labs technology can harness existing utility and communication equipment to power sensor nodes and networks. Harvesting energy from radio and TV broadcasts, cellular networks and magnetic fields from electrical distribution infrastructure, can provide the power needed for critical, long-range sensors.

• Smart Homes – Our wireless power technology allows for the proliferation of embedded sensors that never need to be maintained. So, smart homes of the future will be highly functional and aware, as well as aesthetically pleasing.

• Health and Medical – Wireless power can enhance healthcare by enabling novel treatments, such as long-lived medical implants, as well as improving hospital operations through patient and facility monitoring.

• Space and Military – Despite strides made to improve rocket technology and reduce the cost of lifting cargo into orbit, liftoff weight remains a critical metric that must be minimized. Eliminating wires and leaving power cables at home can help.