True Autonomy brings cutting-edge technology into one of humanity’s oldest, most valued industries: construction. Below is our recent interview with Michael Lawrence, CEO at True Autonomy:

Q: Michael, what is the best way to describe True Autonomy?

A: We develop software to enable small construction equipment to see its surroundings and function appropriately. Our first target market, concrete polishing, is an ideal use case. After a Walmart or Best Buy retail store is constructed but prior to racks of items or customers enter the store, the concrete floor must be polished. This open, controlled environment is perfect for our solution. True Autonomy’s system attaches to existing machines to

- Let the machine know where it is within the building (localization)

- Plot a course (path generation)

- Follow the course allowing the machine to do its job (path tracking)

- Account for unexpected or initially unseen obstacles (obstacle detection and avoidance)

We work with third party suppliers to manufacture the add-on and directly with the OEMs to market and distribute the final product.

Recommended: MineAMask Helps Users Donate Spare CPU Power To Generate Funds & Fight COVID-19

Recommended: MineAMask Helps Users Donate Spare CPU Power To Generate Funds & Fight COVID-19

Q: Michael, let’s start with your background. What were you doing before True Autonomy?

A: I started my professional career developing mine detection algorithms used by the US Navy after receiving an undergraduate degree from Rice University (B.S. Electrical Engineering with a focus on Digital Signal Processing). I quickly pivoted to learn more about business by joining Accenture, eventually entering Carnegie Mellon University’s Tepper School of Business for my MBA (where I focused on Technology Leadership). I specifically chose CMU’s program because of their strong connection and history with robotics. It would still be a few years after earning my MBA (during which I worked at Boehringer Ingelheim, a German pharmaceutical company, in a variety of cross-functional roles) before I found the right fit for my vision of a Wall-E-esque robotic solution for small construction equipment.

Q: Can you tell us something more about the product? How does it work?

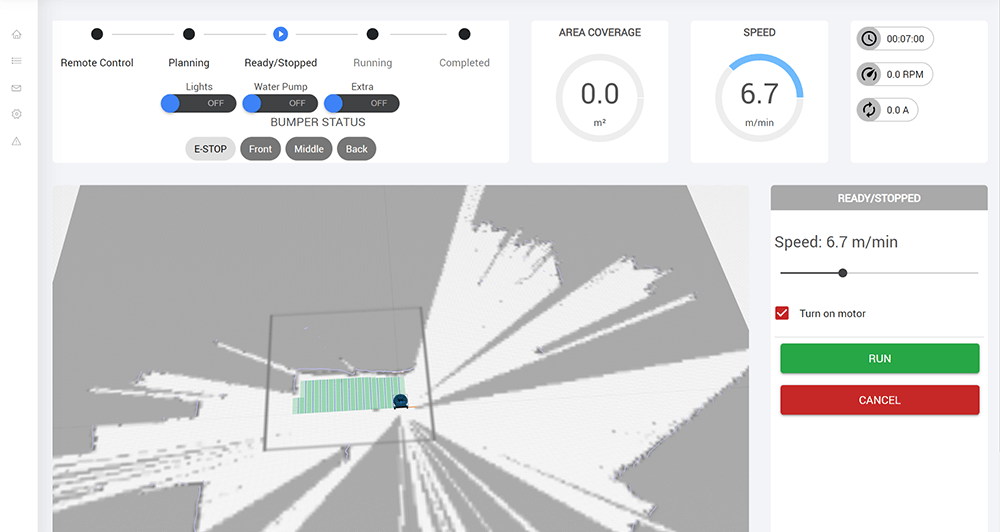

A: The product comprises a control panel, rotating LIDAR sensor and three depth cameras. It is assumed a laptop, tablet or phone will be used to access the locally-served user interface (you log onto the system’s router like you would your home WiFi and then navigate to a webpage to access the user interface). The rotating LIDAR feeds the system a 2D view of its environment; it measures how far walls and other features viewable from the height of the laser are from the machine. True Autonomy’s system takes this information as well as information from the motor encoders while the machine is in motion to provide feedback on the machine’s position and workspace. The 3D depth cameras track the area near to the machine to watch for obstacles.

That all may sound complicated, and it can be, but our User Interface (UI) simplifies the technology so that contractors don’t have to fumble with complex technology and can instead focus on getting the job done. Most of the focus of our UI is a map we generate. The contractor can specify the size of the job and our system will automatically create a path for the contractor to approve. Once they’ve done so, the contractor starts up the engine and presses “Run” and the machine does the rest.

Q: Why is now the time for a technology solution like ACP-100?

A: For this kind of technology the question has never been if but when. Starting with national efforts like DARPA’s Grand Challenges and continuing with Google, Tesla, Uber, Ford and a huge number of other large companies pouring literal billions of dollars into the development of the backbone of autonomy, the time for a practical debut of autonomous technology for smaller machines is nigh. While ambitious, the goals of those larger companies are extremely daunting: how do you let a car know it’s on the right path when its driving 70 mph on an unmarked road in the middle of a blizzard? By taking a more measured, baby-steps approach, True Autonomy is able to solve much simpler but still meaningful business problems on a smaller scale. Coupled with the massive improvements in perception available through open source efforts and a continued improvement in both functionality and cost for sensor technology, I believe we have reached the inflection point at which autonomous technology becomes commercially viable for small to medium scale endeavors like concrete polishing.

Recommended: Sentrium Provides Full-Cycle Digital Transformation, Custom Web, Mobile Development, And Back-Office Support

Recommended: Sentrium Provides Full-Cycle Digital Transformation, Custom Web, Mobile Development, And Back-Office Support

Q: What are your plans for the future?

A: True Autonomy has demonstrated both the technical feasibility and market demand for small scale autonomy. However, as with most wholly new products in most industries, the construction industry is slow to adopt. So True Autonomy’s mission in the near term is to continue to educate users on the technology through product demonstrations, panel discussions and trade show exhibitions. In the longer term, we will grow our market within concrete polishing, continue to look for partners in adjacent spaces (like power troweling or autoscrubbing) and improve our core technology.

Activate Social Media: