Worximity delivers connectivity solutions to help factory managers take real-time control of their production, monitor activities and correct the problems. Below is our recent interview with Emilie Lachance, Marketing Director at Worximity:

Q: Emilie, could you explain the function and advantages of your technology?

A: Since its start in 2011, Worximity has been striving to develop connectivity solutions to help factory managers and team members monitor their production in real-time.

Reporting and data are key elements to run an efficient manufacturing facility. In the Industrial Internet of Things era (IIoT), the weekly paper reports are replaced by real-time data collection, intelligent big data aggregation, and relevant KPI (Key Performance Indicators) display.

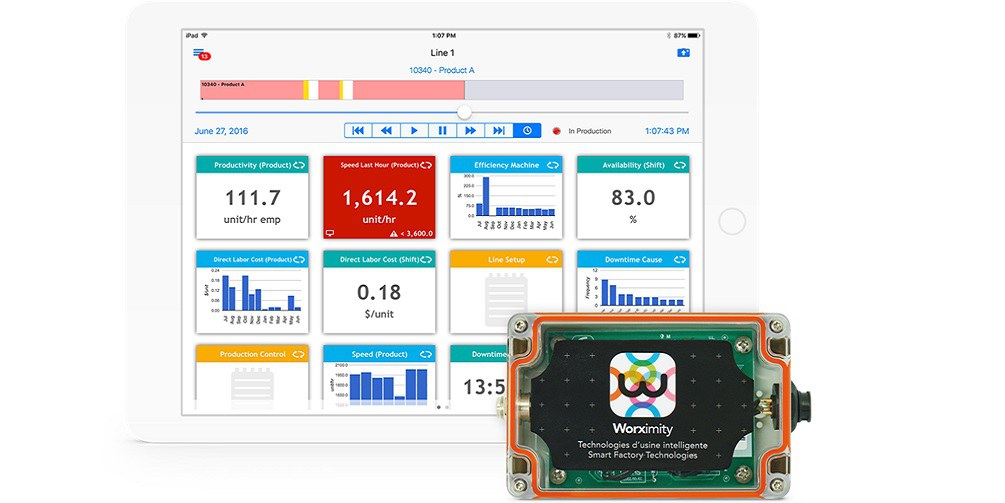

Our TileConnect smart sensors connected to production lines or equipment collect data that are automatically transferred to the cloud and then shown succinctly and in a user-friendly way on our TileBoard dashboard.

With TileBoard, an cloud-based application for mobile devices and also its web-based version, Worximity has created a more intuitive and easy-to use dashboard. All the essential information is presented in smart tiles, fed in real-time by smart sensors strategically placed on production lines. Having an accurate picture of your operations will give you an edge on the market and allow you to be more competitive.

Recommended: ReportLinker Helps You Turn Data And PDF Documents Into Structured Knowledge

Recommended: ReportLinker Helps You Turn Data And PDF Documents Into Structured Knowledge

Q: What advantage does Worximity Technologies have over its competitors?

A: Our business model is based on affordable monthly fees and our technology does not request any heavy investment whatsoever. As the TileConnect sensors are connected directly on the plant’s wifi, no extra infrastructure is needed. The TileConnect wireless smart sensors can be installed on all equipment, old or new, in less than an hour. The collected data is automatically sent to the TileBoard application dashboard.

Q: You’ve recently concluded a partnership with KEOPS & Datahex; tell us something more?

A: These two strategic partnership agreements help improve both of our offerings and speeds up the conquest of new markets in the manufacturing industry. Datahex offers paperless digital forms providing real-time analysis collected on the production floor while KEOPS is an integrated IT solutions for manufacturers. It makes both of them natural partners to implement our connectivity technologies in factories. Together, we make factories smart!

Recommended: Freight Brokerage Firm GlobalTranz Takes Freight Management Technology And Services To A New Level

Recommended: Freight Brokerage Firm GlobalTranz Takes Freight Management Technology And Services To A New Level

Q: Who is your ideal customer and why?

A: Our ideal customers are small and medium manufacturers who have a need to monitor their production lines or equipment. They strive to enhance their performance and are looking for an easy and low-cost solution to improve productivity and efficiency. They want to become a paperless factory and improve engagement across managers and employees.

Q: What are our plans for 2017?

A: We were just funded 2M$ to keep on growing and find visionaries to help us increase manufacturers’ performance. We currently are developing worldwide channels to spread our smart factory technologies across system integrators, OEMs and services companies. Worximity is on the right path to conquer the world with a team full of energy and passionate about helping manufacturers from all over the world increase their performance.

Activate Social Media: