* – This article has been archived and is no longer updated by our editorial team –

Below is our recent interview with Lior Akavia, CEO at Seebo:

Q: Could you provide our readers with a brief introduction to Seebo?

A: The Seebo mission is to empower manufacturers to predict and prevent disruptions in quality and downtime.

Our Industrial IoT Platform combines visual, code-free tools for process and data modeling, automated root cause analysis, predictive analytics and digital twin visualization. These capabilities enable us to tailor our solutions to clients’ specific needs and easily adapt the solutions post-deployment.

Our clients include manufacturers across industries like Grundfos, Stanley, Proctor & Gamble, Ralph Lauren, and many more. These companies are harnessing Seebo to increase overall equipment effectiveness (OEE), minimize maintenance costs, and continually improve production quality.

Q: What makes Seebo stand out from its competition?

A: At Seebo, we’re pioneering process-based AI solutions that inject the customer’s production line processes and knowledge, together with data from OT and IT systems, into machine learning.

This means our customers can solve complex quality and downtime problems with simple tools – and without mastering data science.

Q: Can you give us insights into your platform’s features?

A: We offer three primary solutions: predictive maintenance, predictive quality, and condition monitoring. Our platform provides manufacturers with tools for quick, code-free configuration and customization of these solutions:

● Modeling and Simulation – Users graphically model the solution’s functionality. Then, Seebo generates an automatic digital prototype: a simulation of the solution which validates your solution’s functionality and ensures that all the necessary elements are included before internal buy-in and implementation.

● Process-Based Predictive Analytics – Seebo automatically translates the IIoT Model’s business use cases into rule-driven alerts, and uses machine learning to deliver actionable insights.

● Automated Root Cause Analysis – This tool gives plant investigation teams fast, accurate insight into the early symptoms of process disruptions, making it easy to pinpoint and mitigate the root causes.

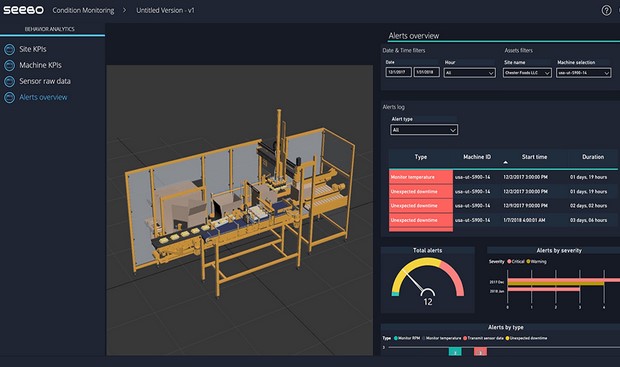

● Digital Twin Analytics – Seebo provides a unique visualization tool in our digital twin. It’s a virtual model of your production line solution and both historical and real-time data which enables teams to drill down into their assets and get contextualized insights into their production process.

Q: What in your view is the biggest barrier to IIoT deployments?

A: Manufacturers constantly face unexpected events that disrupt uptime, quality, and throughput. In order to understand what’s happening and solve problems with IIoT deployments, it’s not enough to analyze machine-generated data. That data, by itself, is incomplete. You need to aggregate OT, IT, and Process data, so that you can analyze the data from your machines in the wider context of your production environment.

Here’s what I mean:

There is an entire world of data around the machines that affect their performance and results: the products produced, the raw materials used, production quality results, production process flows, and production recipes.

Once these different data sources have been gathered together, manufacturers need tools to make sense of their data – and that’s no easy task. Successful IIoT deployments rely on accurate insights from data; however, managers and engineers can waste days and weeks sifting through irrelevant data in order to pinpoint the data that can give them insight into the business problem at hand.

Finding the right machine learning and AI tools to help you prioritize and make sense of the data is essential for successful IIoT Deployment.

Recommended: Overpass – Reinventing The Way You Connect With Customers

Recommended: Overpass – Reinventing The Way You Connect With Customers

Q: How does a company succeed in Industry 4.0?

A: Manufacturers should keep in mind that Industry 4.0 is not a destination; it’s a journey. In taking it, companies must find a way to deliver continuous business value through innovation, ideally every quarter.

The first step to a successful Industry 4.0 journey is to have a clear end goal. Manufacturers should start by accurately identifying their top pain points, then find the IIoT solutions that will address their specific business problems, and their unique production line.

Q: What can we expect from Seebo in the future?

A: We want to enable our customers to do more and more with their industry 4.0 initiatives independently, and become experts in their specific solution. In other words, our customers will use the Seebo tools themselves to adapt their industry 4.0 solutions at the speed of their growing business.

Activate Social Media:

Recommended:

Recommended: