Below is our recent interview with Matthew Kleiman, CEO & Co-founder of Cumulus Digital Systems:

Q: What is Cumulus building?

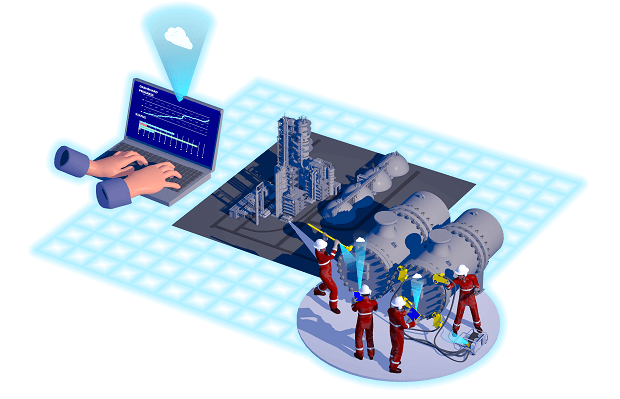

A: Cumulus is building the Internet of Tools to eliminate accidents, unplanned downtime, and re-work caused by poor work quality in industrial maintenance and construction. Manual work in industrial maintenance and construction lags far behind other industries on the road to digitalization. Available solutions are mostly siloed, paper based, provide little real-time data, and offer little accountability at the individual worker level. Inadequate transparency and accountability often result in poor work quality, leading to accidents, rework, and unplanned downtime. Our Internet of Tools platform collects data from digitally-enabled tools in the field to provide a single source of “truth” for real-time quality assurance and progress tracking. We replace the need for expensive and time-consuming inspections to verify the quality and duration of tasks with software and tools that improve speed and accountability.

Recommended: Meet Vinpower Digital – Company Focused Specifically In The Digital Storage And Duplication Market

Recommended: Meet Vinpower Digital – Company Focused Specifically In The Digital Storage And Duplication Market

Q: What are some of the real-world results enterprises can expect with your solution?

A: Cumulus helps our customers dramatically improve work quality and transparency. For example, our flagship product, the Smart Torque System, focuses on work quality in assembling bolted joints. Improper assembly causes about 20% of leaks at refineries and chemical plants. Our customers in those industries have almost completely eliminated leaks caused by workmanship errors, saving millions of dollars in unplanned facility downtime and preventing harm to people and the environment. Our customers are also able to reduce their quality control and data review time by about 60% because everything is digital, saving many hours of paperwork.

COVID-19 has also highlighted the benefits of remote inspections, which are enabled by our system. For example, in April 2020, travel restrictions prevented a quality inspector from traveling to our customer’s offshore facility in Southeast Asia to oversee a planned maintenance event. This would ordinarily have resulted in the postponement of this important activity. However, using the Cumulus system, the QA inspector was able to approve the work remotely from shore without having to physically visit the facility, allowing the maintenance work to be completed on time and on budget.

Q: You’ve recently raised $8,000,000 in funding; can you tell us something more?

A: This funding round was led by a new investor, GEC, with our existing investors, Brick & Mortar Ventures and Shell Ventures, also participating. GEC is a fantastic partner for us because they have deep experience helping to scale technology companies in the energy supply chain.

Q: What are your plans for the future? Do you have any new features in the pipeline?

A: We intend to use the funding to scale our sales and customer success operations globally and accelerate the development of new capabilities for our platform. We want to add more types of work activities to our platform so that we can grow into the quality assurance platform of choice for all mission-critical, high volume, manual work activities across industries. We will also develop new data analytics and AI capabilities to help our customers get even more value out of our system.

Recommended: Openbase Helps Developers Choose Among Millions Of Open-Source Packages

Recommended: Openbase Helps Developers Choose Among Millions Of Open-Source Packages

Q: What’s the best thing about Cumulus Digital Systems that people might not know about?

A: Most of our team comes from industries where safety and work quality are matters of life and death. Just among my co-founders and myself, we were in aerospace, defense, biomedical systems, and energy, and we all have personal experiences dealing with the consequences of inefficient, paper-based systems and poor work quality. Because of our backgrounds, our whole team is passionate about improving worker and environmental safety and making industrial facilities and construction sites more productive through digitization.

Last Updated on April 4, 2021

Activate Social Media: