* – This article has been archived and is no longer updated by our editorial team –

Below is our recent interview with Jim Morin, President of Worldwide Laser Service Corporation:

Who we are — Worldwide Laser Service Corporation

We are an industrial automation company specializing in the use of laser system integration. Laser Automaton is critical in the manufacturing process and as such the mission of WLSC is to protect products and consumers, reduce manufacturing costs, and provide eco-friendly green manufacturing environments, though the use of laser system integration.

Laser System Automation for marking, etching, and cutting allows WLSC to complete this mission with the following major considerations

Consumers are protected with product identification, expiration dates, lot numbers, track and trace data bases and customized messages from the manufacture.

Manufacturing costs are reduced as scrap rates are significantly reduced or eliminated, requirements to replace blades, saws, printing pads and other items that come into contact with parts is eliminated, and downtime during shift changes or product changeover is significantly reduced.

Eco-friendly green manufacturing environments are created as laser automaton eliminates inks, chemicals, & solvents from the manufacturing process, additionally the use of labels, paper, and vinyl can also significantly reduced or eliminated via laser system integration.

Laser System Integration is a critical item for many industries and WLSC customer base covers a wide range from Semi-conductor and Wafer Manufacturing to cabinet manufactures, the principal industries we work with are:

• Medical Device and Pharmaceutical Products

• Semi-conductor and Wafer Fabrication

• Drilling thin films and ceramics

• Asset Management and Product Track and Trace

• Color laser marking plastics

• Laser Etching and laser marking metals

• Laser Cutting Plastics

Since our founding in 1986 for the past 32+ years WLSC has strived to provide automation solutions to our customer base, integrated with data bases, and tied to production systems providing laser platforms in the 10.6µm and 9.3µm for Co2 lasers, 1067-1067nm for YAG-Fiber laser application, 355nm for UV laser applications and 532nm for Green laser requirements.

Recommended: The Inside Revolutionizes How Consumers Approach Infusing Fashion Into Their Homes

Recommended: The Inside Revolutionizes How Consumers Approach Infusing Fashion Into Their Homes

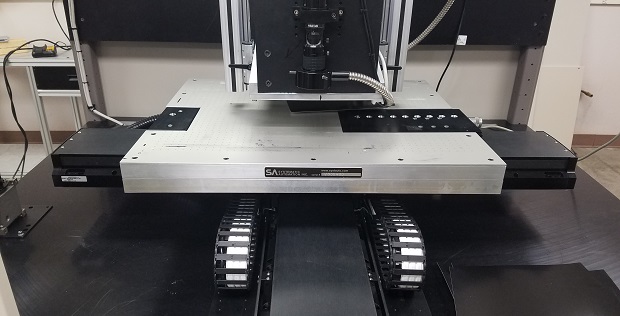

Recently WLSC introduced new models to the linear series and also to our drilling series of lasers, in the coming months and years WLSC plans to offer additional integration features and continue to provide all the newest controller software and system technical advances in an attractive, eco-friendly, and cost effective package. At Worldwide Laser we KNOW Lasers, and we look forward to hearing from you.

Activate Social Media:

Recommended:

Recommended: