Below is our recent interview with Gonen Ziv, CEO of WonderLogix:

Q: Could you provide our readers with a brief introduction to WonderLogix?

A: WonderLogix is a leading innovator in coding-free industrial automation systems. We are disrupting the world of industrial automation with our patented technology that enables designing and programming control systems in plain English – no programming knowledge required. The platform automatically generates PLC code and the supporting documentation. WonderLogix is used at industrial facilities in many market sectors including energy, water treatment, biotech, food & beverage, oil & gas and more.

We were excited to be awarded a $2.2M USD equity-free investment by the European Union’s Horizon 2020 SME Instrument program last year. The SME Instrument invests in companies that demonstrate world-class technology innovation and high-profitability potential.

Q: You’ve recently announced support for Siemens’ TIA Portal; Could you tell us something more?

A: We recently expanded our capabilities to include the Siemens TIA Portal. With this integration, Siemens Programmable Logic Controllers (PLC) can now leverage the many advantages of the WonderLogix software platform, including increased accuracy due to safety and diagnosis features, enhanced efficiency and ultimately shorter commissioning times and easier software maintenance.

When combined with the current support for Rockwell Automation’s PLCs, the WonderLogix platform now supports a vast majority of PLC implementations worldwide. All our clients can import existing functional blocks for re-use in designing new systems or upgrading existing ones.

Recommended: The Q&A With Ottawa’s Nick Gamache On Transition From CBC To Elections Canada

Recommended: The Q&A With Ottawa’s Nick Gamache On Transition From CBC To Elections Canada

Q: Can you give us insights into your product? What makes it a game changer?

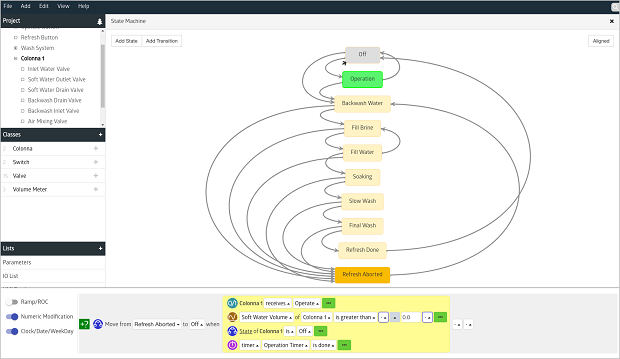

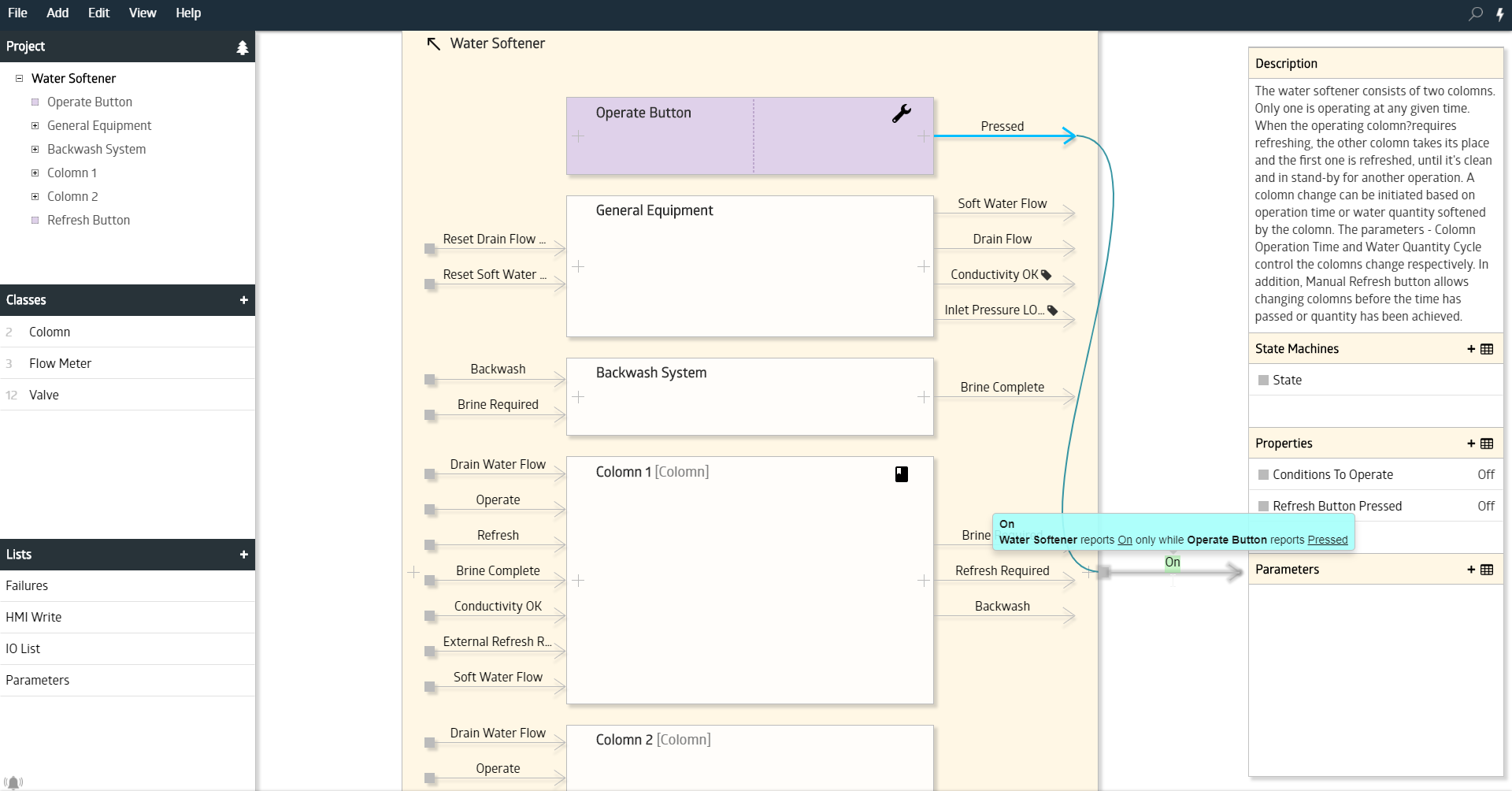

A: Our solution is unique and innovative. We have a patented design platform for defining process specifications visually. WonderLogix uses predictive English syntax support with automatic code generation capabilities, eliminating the errors caused by manual coding. We are in discussions with the ISO organization about establishing a standard for designing industrial control systems based on our revolutionary concepts, such as the use of state machine diagrams.

We are proud that our clients report quantifiable results, such as getting their systems to market at least 3 times faster. Our platform enables our clients to create the industrial process design from their process requirements without the need for intermediaries. Even professionals without formal PLC programming experience can implement industrial automation projects. “WonderLogix takes away the hurdle of learning any of the standard PLC programming languages. It gives you a simple interface to build your system, without requiring your system to be simple,” said Alex Marcy, President, Corso Systems.

Our clients can simulate and test process prior to commissioning and monitor and troubleshoot processes in real-time once their system is up and running. We offer tools that ensure smooth upgrades, documentation tools and data analytics. Using WonderLogix helps safeguard IP by keeping automation design in-house.

Q: How complicated is process automation?

A: One major challenge in designing process-based industrial automation systems is knowledge transfer. There is a communication gap between process specialists and industrial control programmers. Process engineers define how a facility should operate. Because these definitions have no standard format, they are often vague, inaccurate and incomplete.

Control engineers then program the facility’s PLC according to the process engineers’ definitions. There are often misinterpretations and misunderstandings.This antiquated coding environment lacks safe programming methodologies, creating buggy and error prone systems, with negative outcomes such as:

– 70% delay in commissioning time

– 20% of the root causes of processing accidents

– 5% of process industry output loss, due to unscheduled downtime

There is also a widely acknowledged talent shortage. Forty-nine percent ofsystem integrators say that hiring engineering talent is their key challenge for scaling their businesses.

WonderLogix helps companies meets these challenges. In the words of Ammar AL-Naseri, Design Engineer at Fuji Electric: “WonderLogix is the future of the automation industry. It’s going to have a big impact on the traditional implementations of the PLC by removing complexity and reducing project times for customers, regardless of whether they have a background in conventional ladder logic programming.”

Q: What are your plans for the future?

A: We are in the process of creating a global WonderLogix community and an adjacent ecosystem. In addition, we will be bringing support to additional PLC platforms, adding real-time alerts and incorporating dashboards with data analytics that measure the efficiency and productivity of the operating plants, as we literally sit at the heart of the system.

Our vision is to become the de-facto coding-free platform for industrial automation design, commissioning and operations.

Activate Social Media:

Recommended:

Recommended: